Buying a multi-million dollar horticultural lighting system is a big undertaking. We wrote this guide with our insider know-how to help businesses make the right decisions.

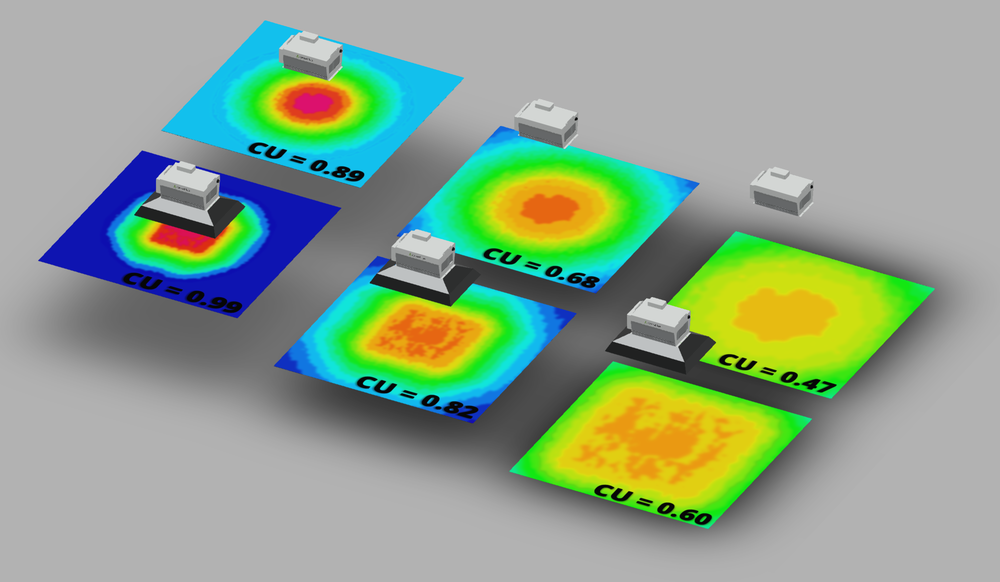

1. Understand the concept of Coefficient of Utilization

This is a measure of how much PAR from your grow lights actually falls onto your plant canopy. Everything from light selection, building materials surrounding your plants, light layout, bench spacing, and light mounting height affects this number. You can read more about CU in our blog post Understanding Coefficient of Utilization

2. Consider the efficiency of your lighting layout and cultivation space

Arrange your lights and plant canopy into grids, and avoid narrow rows and ‘islands’ that lower your coefficient of utilization. Select reflective materials for wall and floor coverings, since light that doesn't fall directly onto your crop can be reflected onto the canopy instead og getting absorbed by dark materials.

3. Research certified lights with DLC

Research lights on the Design Lights Consortium Qualified Products List. Most importantly, be sure to understand the DLC Surveillance process, which is new in 2024. Energy incentives for grow lights will require that you select DLC certified grow lights from the Horticulture Qualified Products List (QPL). In the future, energy incentives will also require DLC certified grow light controllers.

4. Take your electrical infrastructure into consideration

If you are planning to install a large number of grow lights, take a close look at your electric utility connection. Some important questions to ask:

- Do you have the electrical service to support the number of lights needed?

- How much electricity service is currently routed to your location?

- If you have the required electric service, do you have the required transformers, and if you don't, what is the lead time for the necessary transformers?

- Do you have 277VAC electrical service? Many commercial buildings have 277VAC service for lighting, and many grow lights support 277VAC input.

- Do you have 480V service? If so, you may be able to use grow lights that support 480VAC input, which can reduce the amount of transformers needed to deliver power to your lighting system

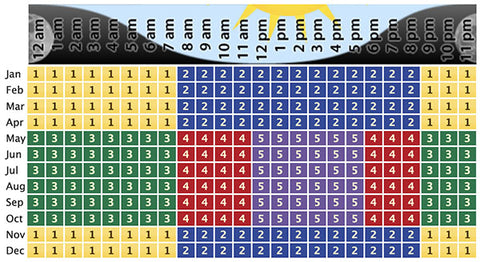

5. Research your utility rates

Most utility companies have dedicated account representatives who can help guide you through your bill and toward the best utility rate for your needs. Work with your utility to determine whether you may qualify for a more cost effective rate plan based on your electricity demands, and consider the schedule of your operations and lighting loads around demand charges.

You should pay close attention to your variable time of use pricing and demand charges related to the peak energy consumption for your faciliy. Planning your lighting system and control schedule around these items can save up to 70% on your utility bill.

6. Shave peak energy demand for your grow lights through scheduling & zoning

Indoor farms have flexibility to break large lighting layouts into multiple zones, and schedule lighting loads in sequence as to reduce peak demand.

Greenhouses can use a similar strategy by defining maximum lighting setpoints on grow light controllers during peak hours.

7. Reduce peak demand with batteries

If you have high demand charges or electricity rates, consider battery energy storage - large scale battery systems are more cost effective today than ever, and can shave off significant peaks from your electricity demand. GrowFlux and its partners can help assess the return on investment for a battery energy storage system (BESS) that works with your horticultural lighting system.

8. Look for utility incentives and rebates

Utility rebates are available throughout North America to cover the upfront cost of horticultural lighting systems. It is important to keep in mind that nearly all of these programs require pre-approval, meaning that you need to file applications with your utility before procuring your lighting system.

GrowFlux can help identify and execute on rebate opportunities, as well as connect you with lighting manufacturers who best fit your needs and budget. Since we are manufacturer agnostic, we are in a position to provide you with the best unbiased recommendation for your needs.

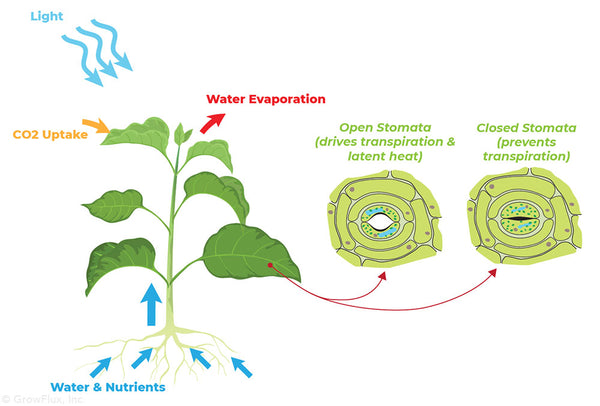

9. Consider latent heat

When grow lights are switched off from full intensity, the open stomata in your crop results in a large amount of transpired moisture, creating an undue latent heat burden on your HVAC system which costs money. Use grow light controllers with sunset dimming profiles to gradually turn down lights at the end of the photoperiod to help your crop’s stomata close when the lights turn off.

10. Understand dimming

Ensure your lights have dim-to-off capability, and understand the minimum dimming level. Not all lights can dim below 40% or 10% intensity, and some lights don't support dim-to-off. Read more about dim-to-off here.

11. Understand the cost of control systems

Some control systems can contribute to higher capital cost, so be sure to obtain a comprehensive quotation for your controls that includes installation if necessary. If you are installing cabinet controls, be sure that you have the required wall space for the panel itself and the supporting conduit. Consider using GrowFlux’s grow light controllers to eliminate capital intensive control systems.

12. Control signaling

Consider how your control system physically connects to your lights. Some manufacturers don’t include dimming interface cables, and some cables require manual wiring. If you are buying a lot of lights, this manual wiring step can translate to many hours of labor and project delays. GrowFlux offers plug and play sealed cabling solutions for large projects.

Ensure that the grow light controllers you are considering are compatible with your lights and can support the number of lights and lengths of dimming signal cables you plan to install.

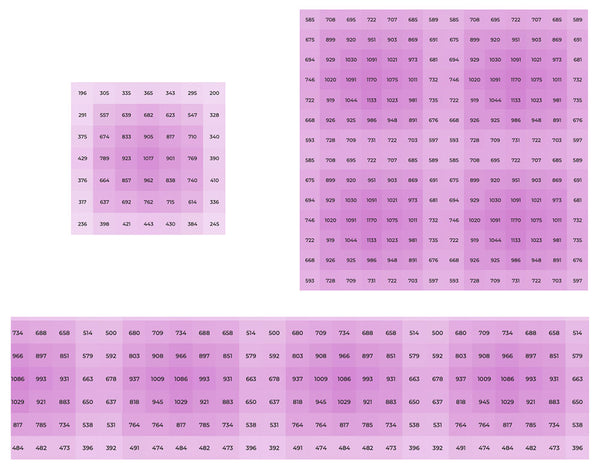

13. Obtain a light plan from your grow light supplier

If you are not able to obtain a light plan, some manufacturers offer PAR maps to aide your planning. If PAR maps are available, be sure to choose the PAR map that most closely represents your use case, since arrays of lights will have entirely different results for intensity and uniformity from single light PAR maps.

If you are soliciting quotations from more than one manufacturer, give each manufacturer the same information so they can create a light plan that can be compared to competitive quotes. At minimum, you should provide the following information to a lighting manufacturer when requesting light plans:

- Floor plan sketch showing total canopy area and dimensions as well as any corridors or spaces that should not be lit

- Ceiling height

- Floor and wall materials

- Maximum mounting height where lights can be placed

- Desired mounting method, truss or mounting area spacing, if applicable

- Target supplemental light levels in μmol/s/m2 PPFD units

- Canopy minimum, average, and maximum height

- Number and layout of control zones needed with unique lighting settings

14. Review light plans from lighting suppliers

When you get a light plan from a lighting manufacturer, ensure that the light plan is not obscuring uniformity issues. There are subtle ways that light plans can hide hot or cold spots through the use of color scales in diagrams or the placement of analysis points. Ensure that analysis points are placed directly under lights and between lights in the analysis plane so you can understand the peak intensity below the lights as well as the lowest intensity on your canopy. You will need to determine how much PAR uniformity matters to your business, as high uniformity systems may translate to higher costs.

If you are growing in a greenhouse, consider how much light the luminaires may be blocking as some lights are larger than others - this is usually out of the scope of a light plan analysis.

Ensure that your light plan accurately represents the wall materials and floor materials, as these can contribute to overall lighting performance.

15. Make sure you have your accessories covered

Ensure that the price your lighting manufacturer quotes includes power cables, dimming cables, and mounting hardware. Some manufacturers may give an off-the-cuff price per light that does not include these required accessories to appear more competitive.

16. Look at the cost of your power cables

The cost for power cables and the associated electrical outlets can add up. Some manufacturers offer multi-drop power cables that minimize the amount of required AC outlets. These power cables can save a significant amount of first cost not only on the cables, but also on installation labor and reduced electrical fitout.

17. Lead times

Check lead times with your manufacturer. Due to global conflicts, shipping and component lead times may be longer than usual, and can change week to week. Be sure that your manufacturer is providing an up to date lead time that accounts for any delays associated with ocean freight shipping.

18. Look into compliance with standards and safety certifications

Many utility incentives require that lights are certified to certain standards, such as UL1598 or UL8800. If you need help understanding compliance, reach out to us!

19. Local Regulations

You may need to comply with certain efficiency standards if you are installing LED grow lights in California, Illinois, and. Massachusetts.

If you are located in California, you may be subject to Title 24 code requirements, which have certain energy efficiency minimum requirements and require the installation of a control system with the lights. GrowFlux controls are California Title 24 complaint, and our team can help with the required inspections. Chat with us if you have any questions about California Title 24 requirements for LED grow lights.

20. Understand customer support

What does the lighting manufacturer do when lights fail or partially fail? How long does it take to get a replacement or warranty coverage for a light? Ask your lighting manufacturer how problems down the road are handled.

21. Consider using a test lab to verify grow light performance yourself

If you are spending a lot of capital grow lights, you can send one to a test lab to perform integrating sphere measurements to verify performance claims. The costs are a lot lower than you might expect - chat with us if you would like us to connect you to a lab that can help.

22. Post sales support

Does the lighting brand you are considering buying offer support after the sale? Some manufacturers have horticulture experts that can add value to your business by advising on cultivation strategy.

23. Installation logistics & packaging

Have you ever had to unbox 3,000 pieces of equipment and dispose of this amount of packaging materials? Be sure to review logistics with your grow light supplier, because having these conversations upfront can avoid a lot of headache and labor when it comes time to install your grow lights. Consider booking a dumpster with a local recycling partner to handle the packaging materials.